Computational Fluid Dynamics, or CFD, sounds like a complex science, but at its core, it is a sophisticated way of simulating how fluids (like air and water) move. In our work as structural engineers, we use CFD to study how wind interacts with buildings and structures.

Author: Bruno Postle, Associate Director, London, UK

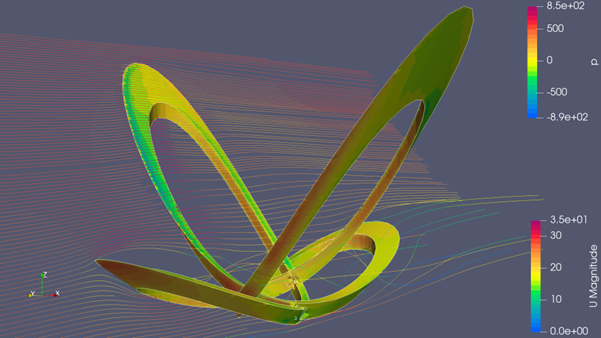

Imagine a virtual wind tunnel where we can see how air flows around a building or structure, all simulated in a computer. With CFD, we analyse wind pressure, windspeed, turbulence, and the resulting loads on structures. This helps us design safer, more efficient buildings.

Often the particular shape of a building channels the wind to produce highly localised, extremely high, wind-loads that can peel cladding from a building or worse. With CFD we can simulate these conditions by modelling the geometry of the building and its surroundings, adding the wind, and testing what happens.

Another critical application of CFD in our work is forensic analysis. When structures fail, it is essential to understand why. CFD allows us to recreate environmental conditions, such as strong winds or sudden gusts, that may have contributed to the failure. This helps identify the root cause.

It is not just extreme conditions that cause failures, a whole class of problems are caused by resonant effects where two parts of a building, a single part such as a chimney, or two different structures, interact through vortex-shedding at very low wind speeds. This can produce disconcertingly large motions, and potentially structural fatigue failure.

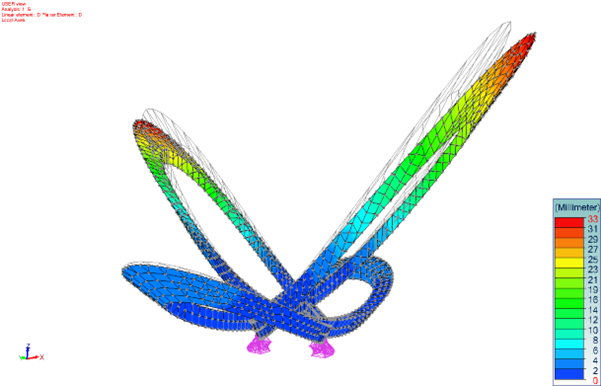

The sculpture depicted in this article was structurally designed by Diales Technical, and it has the kind of complex geometry that benefits from CFD analysis. By constructing a 3D model and a virtual wind-tunnel we can see where the high loads are likely to be. These loads can then be fed back into the structural analysis model to check that the steel is not overloaded.

By combining physics, mathematics, and computer simulations, CFD allows us to visualise and solve problems that would otherwise be difficult or impossible to test in the real world. It is a cutting-edge tool that plays a key role in creating resilient structures while optimising materials and costs.

The author of this article, Bruno Postle, is the lead engineer in our collaboration with artist Gerry Judah. Bruno and the team at Diales Technical bring Gerry's monumental sculptures to life around the world. To find out more about our partnership with this artist, please visit our structural design services page: www.diales.com/structural-design-services

For any enquiries regarding our services in structural engineering, please do not hesitate to reach out to Bruno directly. He will be happy to discuss your projects and vision. bruno.postle@diales.com

ArticlesDigestEuropeGlobal

Share

Share